|

|

DynoSim6

With ProTools™ is a completely new engine simulation just released from Motion Software, Inc. DynoSim6

With ProTools™ is a completely new engine simulation just released from Motion Software, Inc.

DynoSim6 is not only an upgrade from our previous

DynoSim5, it has been completely rewritten from the ground up to include

wave-dynamics tuning aspects from our professional simulation

Dynomation-6.

DynoSim6 not only has better accuracy and many new features, it

still is very easy to use! How can this be? Our Direct-Click™ interface lets

you select any engine component on the left side of the screen, change any

specs, then view the simulation results on the right! It‘s so intuitive,

you‘ll be building horsepower with DynoSim6 in just minutes!

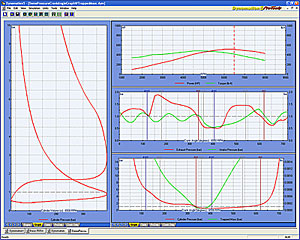

DynoSim6 includes three wave-dynamic displays that let you “see

inside” your running engine! You can determine, at a glance, intake and

exhaust pressures, charge flow, and of course Power, Torque, VE, Airflow,

Valve Lift, and much more! The new displays let you locate and minimize

intake reversion, correct miss-timed exhaust pulses, locate flow

restrictions, and more. DynoSim6 will help you understand why your engine

makes power and show you where you need to focus your efforts to improve

performance.

DynoSim6 also includes advanced forced-induction modeling. Add

turbochargers, Roots/screw and centrifugal superchargers with a mouse click.

Set boost, belt ratios, turbine sizes, A/R ratios, even model intercoolers.

Our all-new DynoSim6 engine simulation is powerful step forward in

technology (was in development for 10 years!). Put it to work for you, and

get the most from your next engine build. Get started with these simulation

extras (included for a limited time): 6000+ Camfiles and 3500+ Lobe Profile

Files (a $130 value). You‘ll find even more engine, flow, and camfiles on

the Internet (the DynoSim Series of engine simulations have over one hundred

thousand of users worldwide). DynoSim6 also comes with a 300+ page, easy to

understand, color user manual (view on screen from within the program).

Bottom Line: DynoSim6 is, simply, the best simulation for the money, and

it’s fun to use, too!

Software Details:

DynoSim6 reveals (otherwise invisible) pressure waves and mass flow in

cylinders and engine passages. It will accurately display how much power an

engine will produce, but it will also show you why it makes that power and

where you should put your efforts to optimize performance!

DynoSim6 is remarkably easy to use. All engine components and specifications

are clearly visible. Change components simply by clicking on any

Direct-Click™ menu. DynoSim6 is intuitive and encourages you to “play” and

test new ideas! With DynoSim6 you’ll quickly optimize performance in any

engine!

DynoSim6

allows anyone to easily and intuitively explore the effects of cam-timing,

intake manifolds, mufflers and exhaust systems, fuels, nitrous,

supercharges, and much more. Motion engine simulations help you understand

IC (internal combustion) mass flow and how it affects performance. DynoSim6

displays internal pressures and flows and let‘s you quickly change

components and specs to optimize cylinder filling. Easy-to-read graphs and

tables give you an unprecedented insight into why specific changes alter power and torque.

unprecedented insight into why specific changes alter power and torque.

DynoSim6 lets you build a

virtually unlimited range of engines, from humble single-cylinder engines to

exotic V-16 racing powerplants. Design, build, and test a 1700hp ProStock

engines, passenger-car daily drivers, Sport-Compact engines with

Variable-Valve-Timing, or motorcycle engines! With nearly one thousand built

in shortblock configurations, a wide variety of domestic and import

induction systems, hundreds of forced-induction choices, and much more!

DynoSim6 will not only meet, but exceed, your engine simulation

expectations!

User Interface And Features:

Despite the

extensive modeling power, DynoSim6 was built from the ground-up to be

intuitive and easy to use, even for beginners exploring engine dynamics for

the first time! Are we exaggerating? Not at all. Supplied with a clear 300+

page Users Manual, any user can learn how finite-amplitude waves (over

10,000 times "louder" than the typical sound waves we hear every day) move,

change, and flow within the engine. By simply "playing" in DynoSim6, you can

view charge reversion, in-tune and out-of-tune conditions, and examine how

cam timing affects mass flow. Because DynoSim6 has been so carefully crafted

for ease of use (see our

Feature-Focus: New Roll-Up Menus),

it is an excellent educational tool on engine pressure-wave dynamics! And

this fact is no better exemplified by the 3D, real-time rendered, cutaway

engine that can be displayed within the program.

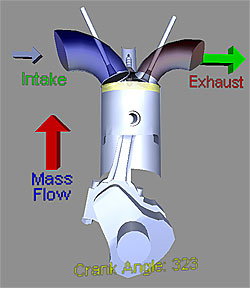

Mass

Flow Visualization:

DynoSim6 includes a 3D cutaway engine with piston, valve motion and

gas-dynamic flow

rendered in real-time and synchronized with the crank-angle

results graphs. Simply drag the graph pointer through the 720-degrees of the

4-Cycle process, watch the engine move through its cycles, visualize mass

flow, exhaust and intake pressure waves, flow velocities, and more! The 3D

engine graphic in DynoSim6 helps you understand the relationship between

crank-angle graphs and actual engine flow. Mass

Flow Visualization:

DynoSim6 includes a 3D cutaway engine with piston, valve motion and

gas-dynamic flow

rendered in real-time and synchronized with the crank-angle

results graphs. Simply drag the graph pointer through the 720-degrees of the

4-Cycle process, watch the engine move through its cycles, visualize mass

flow, exhaust and intake pressure waves, flow velocities, and more! The 3D

engine graphic in DynoSim6 helps you understand the relationship between

crank-angle graphs and actual engine flow.

Technical Overview:

Surprisingly, DynoSim6

includes a great deal more than this. You’ll also find hundreds of other

features including: 1) rapid Iterative™ testing [see below],

2) a comprehensive

CamManager™ tool, 3) import

CamPro, CamProPlus, S96, and CamDoctor profile cam

files, also model and import 10-point cam files (for a limited time,

DynoSim6 comes with a comprehensive library of 6000+ camfiles and 3500+

profile files), plus import cylinder-head-flow and engine files, 3) the

simulation includes several built-in calculators for compression ratio,

airflow conversion, rocker-arm math, cam-timing math, 4) you can run

multiple-engine simulations at once, then perform side-by-side, and

One-Click QuickComparisons™, 5) print professional multi-page

ProPrint™ dyno-test reports, and more. You

are probably beginning to see why we say DynoSim6 is the most accurate,

capable, and complete engine simulation software package ever offered to

engine enthusiast for less than $150.00.

Automatic Updating:

DynoSim6 users receive FREE updates that add powerful new features and

general updates. As a DynoSim6 user, you will benefit from continued

software development by our dedicated engineering staff. Updates are

distributed automatically over the Internet and insure that your simulation

will use the latest technology and include new features and tools requested

by our loyal users. Find out more about

Motion's Automatic Updater.

Unique Motion Software

Features: In addition to advanced simulation

technology, here are some additional features in DynoSim-6 that were

designed and developed by Motion Software, Inc., and are unique to our

simulations:

Direct-Click™ Interface—We

designed a completely unique user interface for our simulations. Engine

components are organized on the left side of the main program screen.

You can select/modify any part by simply clicking on it! Make selections

from a popup menus or enter your own custom values. That‘s it! It's all

right there, visible at a glance: components specs on the left and

simulation results on the right. Our users really enjoy using our

simulations, in part, because they are so intuitive and easy to use!

Motion Updater™—Automatic,

free updates are regularly rolled out to DynoSim6 users

(see our

Feature-Focus:

Motion's Automatic Updater).

We Really Listen to our users requests

for new features and additional modeling capabilities. Over 50

updates have already been sent to DynoSim6 users for FREE! You can‘t

risk running outdated software! That's never an issue with DyomSim6.

Iterator™ Automatic Testing—The

QuickIterator™ and ProIterator™ testing tools add powerful

automated testing and analysis for cam, induction, and other component

selections.

A few mouse clicks and

Motion's

Iterator™ can

"home in" on the best parts combination for you, automatically! Run

hundreds or thousands of tests! The Iterator™ will perform all

data analysis, keep track of all the results, and display the best

combinations based on your testing criterion.

DataZones™—Extends

the graphic-display and data-analysis capabilities of DynoSim6. Using

this feature, you can add additional data “bands or fields” to graphs

which mark ranges for target power values, label extreme pressures,

excessive engine speeds, and more.

ProPrinting™—Turns

simulation results into a comprehensive "presentation" report of

complete dyno-test data. ProPrinting™ features include

custom graphics, a cover page with the name and address of your business

(or your personal name and address) and logo, optional table of

contents, optional text printed at the bottom of each page (can be a

disclaimer, copyright notice or any other text you wish), optional

comprehensive or "mini" glossaries, and a complete listing of all test

data and results at each rpm test point, including additional

engine-data values, pressures, forces, graphs, tables, and more!

Users Manual:

DynoSim6 is supplied with a 300+page,

full-color, on-disk Users Manual (directly accessible from within the

simulation)

and a printed 16-page QuickStart guide

that will get

you going fast. You can download a copy of the Users Manual to review the

capabilities of this software before you buy (a download link is provided at

the top of this page).

Availability:

DynoSim6 is shipping NOW!

For a limited time, your DynoSim6 purchase includes our current

CamDisk with 6000+

10-point camfiles and our new COMP Lobe-Profile Library CD of 3500+

Cam-Profile files (combined $130 value, supplied FREE)! See

Order Form, for

pricing, special discounts and more.

- What You Can Do With

DynoSim6:

-

Find The

Optimum Cylinder Head Port Areas For Best Overall Power And Engine

Response

-

Accurately

Determine The Best Cam Timing For Street, Racing, Any Special

Application!

-

Use New Fitter

To Precisely Model Cam Timing Specifications

-

Predict

Horsepower And Torque With Excellent Accuracy

-

Analyze

Pressure Waves And Their Affect On Power

-

Display Intake

And Exhaust Pressures And Flow Velocities

-

Display

Cylinder Pressures Throughout 4-Cycle Process

-

Build And Test Virtually Any

1- to 16-Cylinder, 4-Cycle Engine!

-

Use Built-In

Engine Math Calculators (CR, Rocker-Arm, Airflow, etc.)

-

Make Easy Component

Selections, Just Point And Click

-

Test Various

Combustion Chambers, Ignition Timing Curves

-

Focus On "What

You Want To See" Using New Roll-Up Menus

-

Use

CamManager™ To Change Timing Specs And Display Cam-Lobe

Acceleration Rates

-

Test Any Of

The 6000 Supplied 10-Point Camfiles

-

For A Limited

Time: 3500+ Cam Profile Files Included With Your Purchase Of

DynoSim6!

-

Run Extensive

Dyno-Test Series Using Exclusive Motion Software

Iterative™

Testing

-

Test Alternate Fuels And

Nitrous-Oxide Injection

-

Model

Spark-Ignition and Compression-Ignition (Diesel) Engines

-

Model a Static

A/F Ratio or use an

A/F Ratio Maps/Tables

-

Optimize Any Graph Display

With One Click Of The Mouse

-

Produce

Impressive Pro-Print™ Reports With Your Logo, More

-

Test Carburetors/Injection,

Stock & Racing Manifolds

-

View And Print Engine

Pressures, Efficiencies

-

View/Graph

Flow CDs, Valve Curtain Areas, Lift Curves, More!

-

Compare Multiple Engines, Use

One-Click QuickCompare™

-

Instantly Switch Between US &

Metric Units, plus Hybrid Selection!

-

FREE Automatic Updating Ensure

You Are Always Running

The Latest Version Of DynoSim6!

Tune These Key Engine

Components:

-

Set/Modify

Atmospheric Conditions During Test

-

Bore, Stroke, Pin Offset, Rod

Length, Rod Ratio

-

Number Of Cylinders (1 to 16)

-

Wedge, Canted, Hemi, Pentroof,

2-, 4- and 5-Valve Heads

-

Intake And Exhaust Valve

Sizes, Flowbench Test Valve Sizes And Pressure Drop

-

1, 2, Or 3 Valves Per Port

-

Enter And/Or

Import Flow-Bench

Data

-

Model Any

Cylinderhead

-

Modify Any

Valve-Event (IVO, IVC, EVO, EVC, Plus Intake and Exhaust Lift)

-

Model

SAE-Standard Cam Timing (0.006/0.050-inch) Or Any Other US/Metric

Standard!

-

Directly

Modify Lobe-Center Angles, Cam Advance/Retard

-

Change Lash And Rocker Ratios,

See Effects On Timing And Power!

-

Compression Ratio From 6:1 to

30:1

-

CR-Calculator

Uses Volume (Burette) Measurements Or Known Values

-

Various Stock And Racing

Intake Manifolds And Exhaust-System Configurations

-

Up To 7000cfm

Peak Induction Flow

-

Any Carburetor (multiple or

single) or Fuel Injection

-

Common-Plenum

or Individual-Runner Induction Systems

-

Turbo And Roots/Screw

Supercharger Pressures, A/R Ratios, Turbine Sizes

-

Model Throttle Position Before Or After

Turbo/Supercharger Inlet

-

Roots, Centrifugal Belt

Ratios, Intercooler Efficiency

-

Several

Fuels: Gasoline, Methanol, Propane, Diesel, Synthetic, More

-

Nitrous-Oxide With Gasoline Or

Methanol

-

Exhaust

Manifolds, Standard Headers, Megaphone Systems

-

Model

Mufflers, Catalytic-Converter Backpressure

-

Model Several

Exhaust-Header Configurations, Pipe Dimensions Displayed

-

Model Standard

And Variable-Valve-Timing Systems (VTEC Method)

-

Overhead Cam,

Pushrod, Rocker, Rocker Ratios

-

Modify Amy

Valve-Event Timing Specifications

-

Lobe Acceleration Analysis And

Modeling Using New “Fitter”

Algorithms

-

Search 6000+

CamFiles In Seconds; Find Cams That Match Custom Timing!

-

And Much More!

DynoSim6: Powerful And Accurate Simulation Technology!

|

|

Comparison Table

Of Motion Engine Simulation Features

DynoSim6 Is Fully compatible with

Windows Vista, 7, 8, and Windows10

(32- and 64-bit).

We Guarantee Your Satisfaction

Or Your Money Back!

DynoSim6

PURCHASE PAGE

Order Your Simulation

Package Today!

FREE—Download

DynoSim6

Users

Manual

(30Mb, Right click, select

Save Target As...)

What's

New In

DynoSim6:

- New "Fitter™" math routines ensure

exacting valve-motion and improve simulation accuracy!

- Valve/Lifter acceleration modeling

improved; uses intuitive, real-world approach.

- New synthetic fuels and Diesel modeling

supported; CRs extended to 30:1.

- Improved Latent-Heat-Of-Vaporization

modeling for all fuels.

- New intake runner-temperature modeling;

perfect for "air-gap" and cold-runner manifolds.

- Set Simulation Convergence to

enhance the power of the FE simulation. Helps resolve complex pressure

waves that can occur on very high rpm engines and with some other custom

engine configurations.

- Displays pressure waves and particle flow

velocities, similar to Dynomation-6!

- New Exhaust options including

stepped-headers, Tri-Ys, and primary/collector size prediction.

- Substantially improved Forced-Induction

modeling and enhanced Compressor-Map displays.

- New Simulation Log error feedback; quickly

diagnose component-combinations issues.

- Confirm port flow data-entry accuracy by

simply viewing the displayed Coefficient of Discharge (CD) values shown

in the Port Flow dialog.

- Tables display Mass Flow (Lb/min or

Kg/sec) for each RPM step; helpful in selecting best blowers or turbos

for any application.

- New Program-Settings dialog let you set

Wheel Horsepower conversion factor, color schemes, key clicks, and other

program startup settings.

- Improved Units handling for US and Metric

systems, plus a Hybrid Units Mode that displays Metric units for engine

components and US units for power and torque!

- Atmospheric selections include 10 popular

dyno-correction standards, or use custom values.

- Every aspect of the program was enhanced,

with our continued emphasis on ease of use.

- Imports all previous DynoSim files with

error checking. Get up and running in no time!

- Purchase now and get the 2018 COMP Cams

Lobe Profile Library (3500+ Profiles) FREE!

- Receive all future DynoSim6 program

updates, including new features under development.

- And, we have your back with our

top-notch Tech Support. Let us know how we can help!

What Makes

DynoSim6 Unique:

-

DynoSIm6 is a highly-refined engine simulation that considerably reduces

the cost and time of engine development and testing.

-

Performs exceptional analysis of camshaft lift, duration,

centerline, and lobe-separation angles. Loads and tests CamPro,

CamProPlus, S96, and CamDoctor cam profile files. Also loads and

tests 10-point cam files.

-

Imports

DynoSim4 and 5 engine, cam and flow files. Upgrade and continue your

development in minutes.

-

Export

DynoSim6 engine files to DragSim and FastLapSim for track testing and

further vehicle analysis.

-

QuickIterator™ provides fast One-Button

testing. Powerful ProIterator™ available for in-depth automated testing.

-

“Look Inside” a running engine. View and analyze intake and exhaust

flow! 3D Cutaway Engine shows mass flow, port velocities,

pressures—synchronized to the crank-angle data displayed in

DynoSim6.

Technical

Specifications:

-

Bores & Strokes (As Small 1.5-Inch Stroke And 2-Inch Bore). DynoSim6 has

a built-in menu library of nearly 1000 shortblocks! Or simply enter your

own custom specs for any engine.

-

Induction models include Domestic and Sport-Compact intake manifolds.

-

Cylinderhead flow modeling supports 1, 2, or 3 Valves Per Port.

-

CamManager™ visually

displays cam timing, models Lobe Acceleration. Imports CamPro,

CamProPlus, S96, CamDoctor Cam Profile Files

-

Supplied With Over 6000+ CamFiles. All CamFiles Load Automatically In

CamManager™!

-

NOW Also Supplied With Over 3500+ FREE Cam Profile Files On A Separate

CD! A full-featured Cam-Profile import dialog is provided within

DynoSim6 that is compatible with a variety of Profile formats, including

S96, CamPro, CamProPlus, Cam Doctor, DoctorDoctor, and more!

-

New

Custom Colors and Graphics, QuickAccess™ dialog and calculator buttons,

more engine data, 300+ page Color Users Manual

-

Simulate 1-to-16 Cylinder, 4-Cycle Engines

-

Graphs

horsepower, torque, VE, engine pressures, flow rates, valve lift,

ignition advance, and much more!

-

Compare up to four engines at once;

pick the best setup in seconds!

-

Test

Detroit Iron, sport compact powerplants, stock or custom racing engines;

just about any IC engine for any purpose.

-

Test

Turbos, Roots Blowers, Centrifugal Superchargers (100's of built-in

compressor maps)! Set Boost Pressure, Turbine Size, A/R Ratios, RPM,

Belt Ratios And More!

-

Evaluate Intercooling with any forced induction system.

-

Combine any induction with any fuel. Use Nitrous-Oxide Injection with

Gasoline or Alcohol.

-

Completely

custom

Windows interface with Easy-To-Use, DirectClick™

Menus, And Enhanced Graphics

-

Graphs fully customizable; display/compare any engine variable. One

rpm-based graph and three crank-angle based graphs.

-

Analyze cylinder and manifold pressures, frictional losses, perform

comprehensive technical analysis.

-

Accurate, State-Of-The-Art, and Fun To Use; Encourages "Play" to help

you discover new power secrets!

System Requirements:

- A Windows-compatible PC with a CD-ROM

(if you do not

have a CD-ROM drive, contact

latherton@motionsoftware.com)

- A fast system processor (recommended 2GHz or

faster) will improve processing speeds; especially helpful for

Wave-Action and

Iterative testing. However, Dynomation will operate on any Windows

system, regardless of processor speed.

- A minimum of 2GB of RAM (random access memory) for

Windows Vista, Win7 and Win8.

- Fully compatible with Windows

Vista, 7, 8 or Windows10 (32- and 64-bit).

Windows95 is NOT supported.

- A video system capable of at least

1280 x 1024 or higher to optimize screen display of engine components

and performance analysis graphics.

- Mouse

- Windows-Compatible

Printer required for test reports

Comparison Table

Of Motion Engine Simulation Features

|

DynoSim6

With ProTools™ is a completely new engine simulation just released from Motion Software, Inc.

DynoSim6

With ProTools™ is a completely new engine simulation just released from Motion Software, Inc.